Solving cable's reliability of flex life

and particulation issues, electrical performance requirements,

space constraints, and various environmental conditions

Solving the flex life issues of moving cables in equipment that seriously affects the production efficiency of automated processes.

Solving the particulation issues of moving cable systems that reduces the yield of products produced in clean rooms.

Solving various electrical performance-related issues that are caused by the high-level requirements with the advancement of equipment technology.

Solving the spatial constraint issues due to the demand for miniaturization of equipment, and various environmental conditions such as high temperature, low temperature, chemical exposure, and high vacuum, etc.

Provide a variety of cable solutions

for the highest level of flex life.

Since the motion patterns and operating conditions of various moving parts of equipment vary widely from one equipment to another, it is not possible to apply a single product type to solve all of them, but rather to select the optimal product and applicable structure for each operating condition. UTRACS provides a variety of cable solutions that can be expected to provide the highest level of operational life by analyzing the conditions, constraints of moving parts in detail based on relevant product technology and experience accumulated over many years.

Provide clean cable systems

and related solutions that minimize particulation.

GORE® Trackless High Flex Cables, the world's first self-supporting cable system for clean rooms, were developed in 2003 and was the beginning of a family of products now referred to as “clean cables” in the industry. GORE® Trackless High Flex Cables were introduced to the market in the mid-2000s and has since been adopted by the display and semiconductor manufacturing industries as a standardized specification for processes where particulation control is essential, contributing to improved yields of related products.

Design, build and deliver a full range of

electrical cable system flexing in automation

equipment to meet customer requirements

We stock or custom manufacture a full range of power and signal transmission cables commonly used for flex applications in automation equipment, as well as support a variety of machine vision protocols that require high-speed, high data rate signal processing (e.g. Camera Link, USB3.1, Ethernet CAT6/7, etc.), each with a minimum of 10 million flex cycles. Depending on specifications and operating conditions, custom designs can extend flex life performance up to hundreds of millions of cycles.

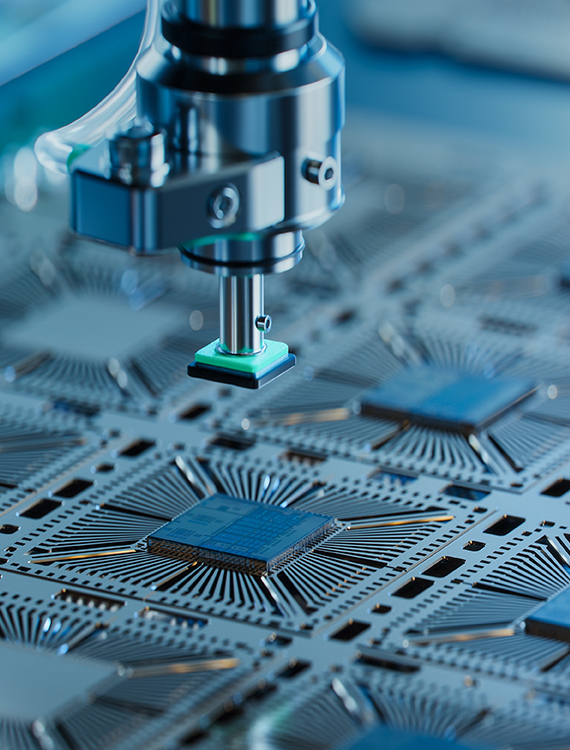

Inspection Machines (AOI)

Pick & Place (SMT)