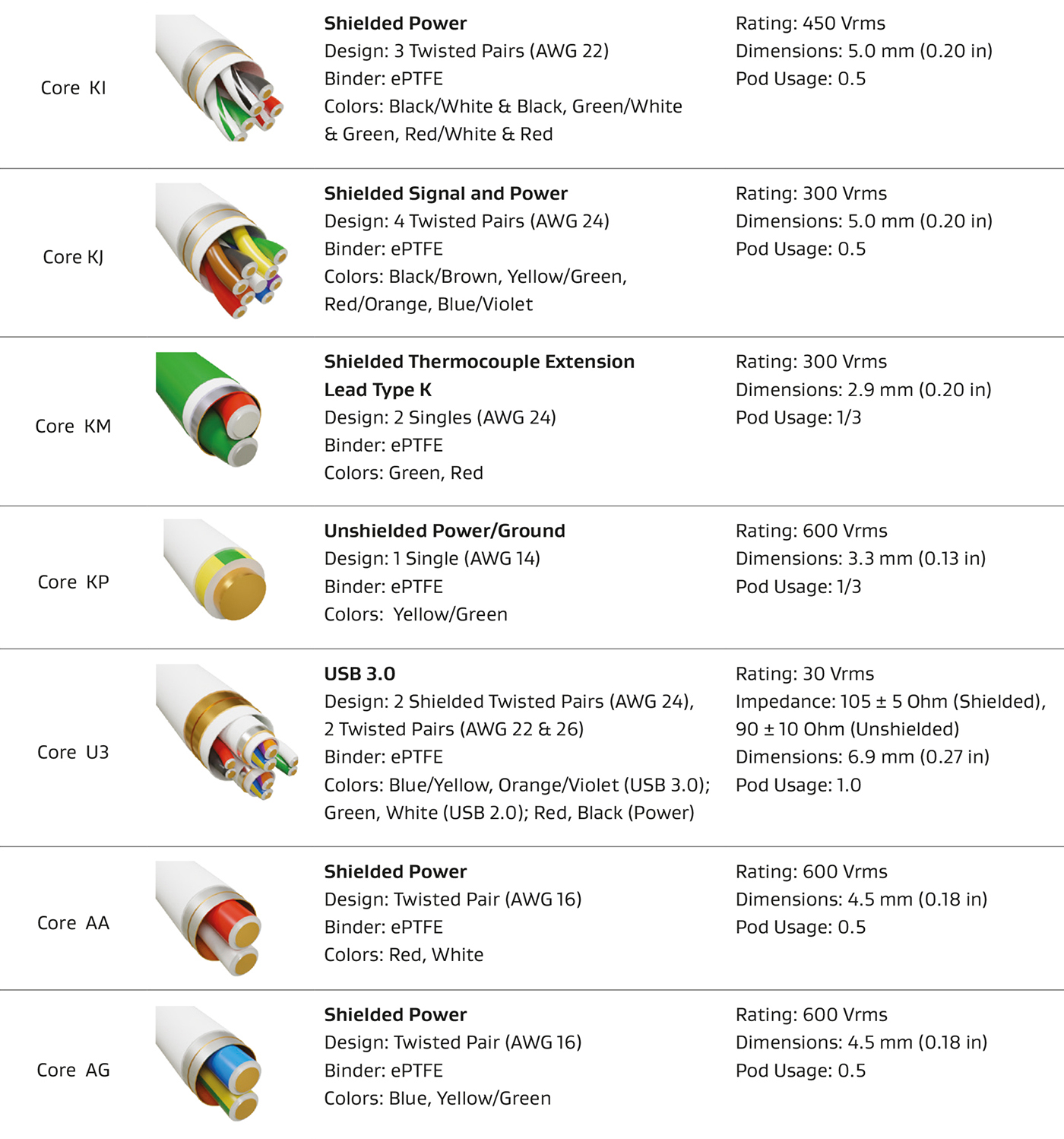

GORE® High Flex Flat Cable

A cable product that is made by arranging multiple cable cores in

parallel inside a flat jacket with a PTFE or ePTFE outer jacket to form a single flat structure.

Multiple strands of round cables are combined to operate as a single cable, making it easy to control the flex motion,

and can support itself without a separate cable carrier for short distances (~ 500 mm).

Even when installed inside a cable carrier, twisting and friction are significantly reduced, making it effective for

cable's flex life and particulation control, and can be configured with all required cable structures. It is mainly used in driving parts of linear motion, but can also be applied to other types of flexing depending on other flex conditions.

Multiple strands of round cables are combined to operate as a single cable, making it easy to control the flex motion, and can support itself without a separate cable carrier for short distances (~ 500 mm).

Even when installed inside a cable carrier, twisting and friction are significantly reduced, making it effective for cable's flex life and particulation control, and can be configured with all required cable structures. It is mainly used in driving parts of linear motion, but can also be applied to other types of flexing depending on other flex conditions.

Multiple strands of round cables are combined to operate as a single cable, making it easy to control the flex motion, and can support itself without a separate cable carrier for short distances (~ 500 mm).

Even when installed inside a cable carrier, twisting and friction are significantly reduced, making it effective for cable's flex life and particulation control, and can be configured with all required cable structures. It is mainly used in driving parts of linear motion, but can also be applied to other types of flexing depending on other flex conditions.

Multiple strands of round cables are combined to operate as a single cable, making it easy to control the flex motion, and can support itself without a separate cable carrier for short distances (~ 500 mm).

Even when installed inside a cable carrier, twisting and friction are significantly reduced, making it effective for cable's flex life and particulation control, and can be configured with all required cable structures.

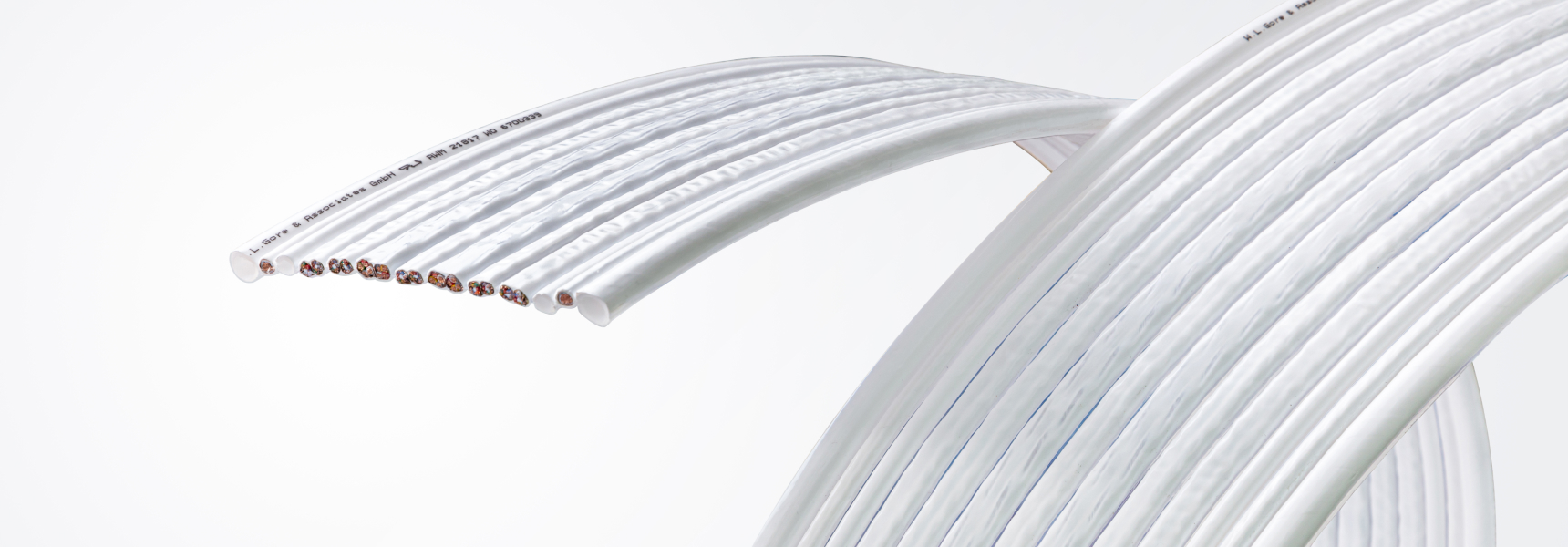

Standard Flat

GORE® High Flex Flat Cables, specialized for Factory Automation equipment, is a product that is customized and manufactured into a flat cable that matches the space, operating conditions,

and expected flex life of the equipment according to the electrical specifications of the automation equipment. Since it is a custom product manufactured according to the customer's needs,

it is possible to manufacture the highest level of cables with the desired specifications without restrictions on electrical specifications and configuration. The existing typical cable system flexing by laying various types and numbers of round cables in a cable carrier according to the electrical specifications, which inevitably causes problems such as particles due to friction, cable breakage, and work time for installation required for numerous strands. GORE® High Flex Flat Cables forms multiple round cables into a single flat surface with an ePTFE or PTFE jacket, which has the advantages of reducing particulate, extending cables flex life, shortening installation work time, and reducing overall weight.

In addition, a separate cable carrier is not required for short stroke length (when securing space within 500 mm of stroke). Considering the maintenance costs and yield loss of existing systems that occur due to the above problems over the life of the equipment, the benefits of GORE® High Flex Flat Cable not only offset the initial cost increase due to the higher unit price of the cable, but also dramatically reduce the manpower and time consumed due to cable problems.

| Property | Value |

|---|---|

| Jacket Material | Expanded PTFE composite |

| Jacket Color | White |

| Core Typesa) | Power, Signal, Fiber Optic, Pneumatic, etc. |

| Max. Self Supporting Stroke Lengthb) (mm) | 500 |

| Min. Bending Radius b) (mm) | 50 |

| Max. Acceleration (G) | 4 |

| Max. Velocity (m/sec) | 4 |

| Expected Flex Life Cycles b) | Max 20 million cycles |

| Temperature Range (℃)c) | -40 ~ 80 |

| Cleanliness Class (ISO14664-1) | 1 |

| Particulation d) (ISO14664-1/ VDI Guideline 2083) | < 0.1 % |

Reference the Cores List of On-demand Flat

Product characteristics, operating conditions, and environmental factors may vary. (For further details, please consult Utracs representative.)

Separate inquiry required for high temperature

Details about the Cable Particulation Study for Cleanroom Environments from the Fraunhofer Institute are available at www.gore.com/particulation

Vacuum Flat

Cables used in vacuum environments require specialized materials and manufacturing processes that meet the required specifications

due to environmental conditions that are completely different from atmospheric pressure.

Gore's cables have been an integral part of NASA's various space development projects since the 1960s.

Vacuum environment-related technologies accumulated over several decades are also being applied to high-vacuum environments such as EUV machines,

which is an essential leading technology for the development of next-generation semiconductors, contributing to the development of the semiconductor industry.

| Property | Value |

|---|---|

| Jacket Material | Expanded PTFE composite |

| Jacket Color | White or Transparent |

| Core Typesa) | Power, Signal, Fiber Optic, Pneumatic, etc. |

| Max. Self Supporting Stroke Lengthb) (mm) | 500 |

| Min. Bending Radius b) (mm) | >10 times of cable diameter |

| Max. Acceleration (G) | 4 |

| Max. Velocity (m/sec) | 4 |

| Expected Flex Life Cycles b) | max 20 million cycles |

| Temperature Range (℃) | -20 ~ 260 |

| Cleanliness Class (ISO14664-1) | 1 |

| Particulation c) (ISO14664-1/ VDI Guideline 2083) | < 0.1 % |

|

Outgassing rate(mBar x l/sec x ㎠)

• H2O (AMU 18) d) • CxHyv (volatile CxHy) (AMU45-100) d) • CxHynv (non-volatile CxHy) (AMU101-200) d) |

• 4.00E-09 • 1.00E-10 • 6.00E-12 |

Reference the Cores List of On-demand Flat

Product characteristics, operating conditions, and environmental factors may vary. (For further details, please consult Utracs representative.)

Details about the Cable Particulation Study for Cleanroom Environments from the Fraunhofer Institute are available at www.gore.com/particulation

AMU = Atomic Mass Unit

IDC RIBBON

Ribbon-shaped flat cables that meet IDC standards are designed to have the highest level of flex life (~ 50 million cycles) in various demanding environmental conditions that require characteristics such as thinness and lightness, chemical resistance, and heat resistance.

Due to the durability, reliability proven in related industrial fields for decades, they are evaluated as the most reliable cables by many customers.

| Property | Value |

|---|---|

| Jacket Material | PTFE |

| Jacket Color | Grey, Black, Red, Green |

| Wire Gauge | AWG26, AWG28, AWG30, AWG32 |

| Wire Pitch(mm) | 1.27 / 0.64 |

| Min. Bending Radius a) (mm) | 40 |

| Expected Flex Life Cycles a) | Up to 50 million cycles |

| Temperature Range (℃) | -65 ~ 260 |

| Cleanliness Class (ISO14664-1) | 1 |

| Particulation b) (ISO14664-1/ VDI Guideline 2083) | < 0.1 % |

Product characteristics, operating conditions, and environmental factors may vary. (For further details, please consult Utracs representative.)

Details about the Cable Particulation Study for Cleanroom Environments from the Fraunhofer Institute are available at www.gore.com/particulation

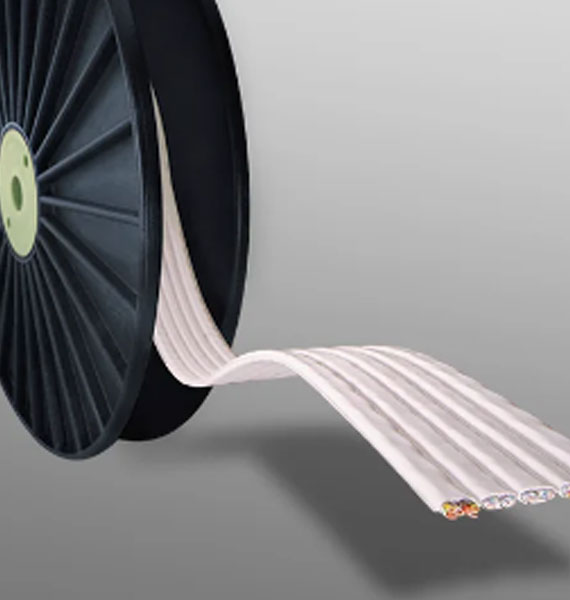

On-Demand Flat

GORE® High Flex Flat Cables is mostly a customized product, and requires a minimum order quantity and relatively long lead time for production.

In order to meet the trend of continuously demanding small orders and short lead times as equipment specifications diversify,

Gore has separated the ePTFE jacket and cable cores, standardized them, and operates a certain amount of inventory, enabling on-demand small-volume production and short lead times.

UTRACS stocks power, signal, and non-specific cable cores used in most common automation equipment to support the customers in timely in a manner.

It is also available to support customized design and manufacturing, if there is no option in the stocks of inventories but requested.

| Property | Value |

|---|---|

| Jacket Material | Expanded PTFE composite |

| Jacket Color | White |

| Core Typesa) | Power, Signal, Fiber Optic, Pneumatic, etc. |

| Max. Self Supporting Stroke Lengthb) (mm) | 500 |

| Min. Bending Radius b) (mm) | 50 |

| Max. Acceleration (G) | 4 |

| Max. Velocity (m/sec) | 4 |

| Expected Flex Life Cycles b) | Max 20 million cycles |

| Temperature Range (℃) | -40 ~ 80 |

| Cleanliness Class (ISO14664-1) | 1 |

| Particulation c) (ISO14664-1/ VDI Guideline 2083) | < 0.1 % |

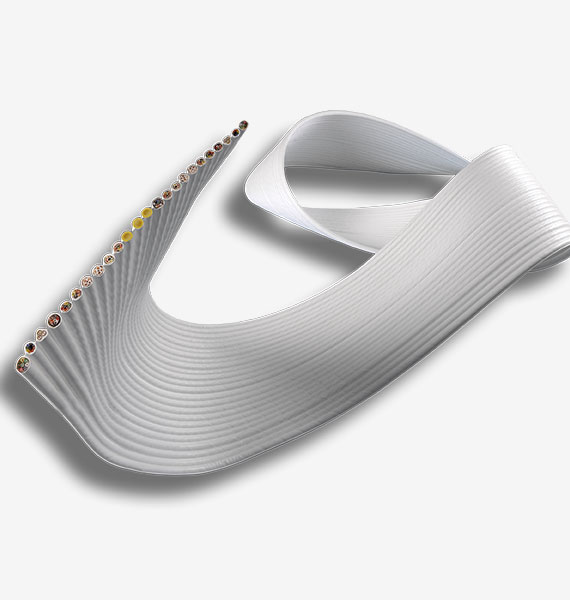

Cable cores selected according to requirements are inserted into a jacket to form a flat cable

Available for short lead times (2-3 weeks) and small quantities (cut to length).

Standardized cable cores are not only the most common power and signal transmission cables used in automation equipment,

but also the wide ranges for high-speed cameras, thermocouples, fiber optics, etc. which are the only reliable options on the market.

Reference the Cores List shown below.

Product characteristics, operating conditions, and environmental factors may vary. (For further details, please consult Utracs representative.)

Details about the Cable Particulation Study for Cleanroom Environments from the Fraunhofer Institute are available at www.gore.com/particulation

List of standard cable cores

Please contact us for any additional cable cores required other than those listed above.