Material Technology

The performance of a cable highly depends on the materials selected for each component, conductor (core, shield), insulation, outer jacket, etc. Gore has been manufacturing cables that meet various and demanding environmental requirements for decades, and has accumulated know-how to select the optimal conductor. In addition, as a company specializing in manufacturing products using PTFE/ePTFE materials, Gore has secured unrivaled technology.

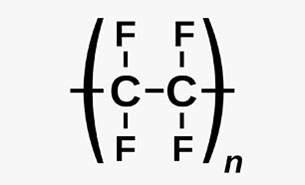

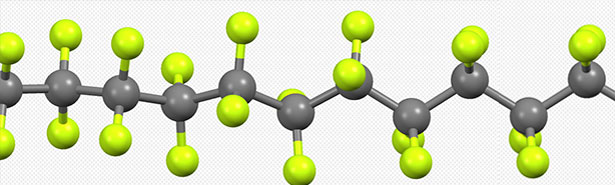

PTFE (Poly Tetra Fluoro Ethylene),

ePTFE (Expanded PTFE)

PTFE has a level of molecular structural stability that no other material can match, making it an irreplaceable and essential material for applications that utilize it.

Gore first began using PTFE to make cables in 1958, and has continued to develop products using PTFE and its proprietary ePTFE compound (e.g., GORE-TEX fabric products) for decades, providing unique solutions for a wide variety of industries and demanding applications, including semiconductors, aerospace, mobile phones, automotive, specialty fibers, and artificial blood vessels.

Due to their inherent excellent electrical and mechanical properties, PTFE and ePTFE are the most suitable materials as insulators and jackets for cables in specialized applications where the highest performance is required.

High chemical stability

of PTFE

The strong bond between carbon and fluorine provides stability that does not break even under extreme conditions (exposures to chemicals, extreme temperatures, vacuum, radiation, etc.). This stability allows PTFE to have unique properties such as excellent mechanical strength, low coefficient of friction, and excellent dielectric properties.

Due to its strong chemical inertness, it is used as an irreplaceable material in many core semiconductor manufacturing processes, and Gore's PTFE cables are essential components in equipment that requires high vacuum environments, such as EUV, the most advanced semiconductor technology process.

PTFE is a material that is basically harmless to the human body because its molecules are very large, cannot react with other biomolecules and penetrate human cell tissues, and its extremely stable molecular structure makes it very difficult to break down to a level harmful to the human body.

Low coefficient of friction

of PTFE

PTFE has the lowest coefficient of friction of any compound, making it the best material for minimizing material-to-material friction without the addition of lubricants. The outer jacket of GORE® High Flex Flat Cables and GORE® Trackless High Flex Cables are made of PTFE or ePTFE, making it the most suitable material for reducing surface friction. The minimal coefficient of friction minimizes particulation when cables come into contact, making it ideal for cleanroom environments such as semiconductor and flat panel display manufacturing.

| Material-to-Material contact combination | Friction coefficient | ||

|---|---|---|---|

| Static | Dynamic(Sliding) | ||

| μstatic | μdynamic | ||

| PTFE | PTFE | 0.04 | 0.04 |

| Polyethylene | Polyethylene | 0.2 | |

| Polystyrene | Polystyrene | 0.5 | |

| Aluminum | Aluminum | 1.05 - 1.35 | 1.4 |

| Copper | Copper | 1.05 | 0.29 |

| Iron | Iron | 1 | |

| Nylon | Nylon | 0.15 - 0.25 | |

| Rubber | Rubber | 1.16 | |

| Steel | Steel | 0.5 - 0.8 | 0.42 |

Low Dielectric Constant

of PTFE

The electrical performance of a cable is largely determined by the dielectric properties of the insulation material.

The insulation properties of the material that wraps the cable's core conductors are represented by permittivity, and the higher the permittivity, the more charge is stored in the material. Therefore, the lower the permittivity, the better the insulation properties. The dielectric constant is the numerical value of the permittivity, which is calculated by setting the vacuum state to 1.

Fluorine compounds such as PTFE and ePTFE are materials with the best dielectric constants, and when applied to cable insulators, cables that require high electrical properties can be made thinner and lighter.

Gore has been manufacturing and supplying cables with PTFE insulation since 1958.

Characteristics

and applications of ePTFE

In 1969, Gore developed ePTFE, a new material that expanded PTFE, allowing it to supply products for a wider range of applications while maintaining the unique properties of PTFE.

ePTFE has a unique porous structure that is impermeable to liquid water but permeable to gaseous water vapor, providing innovative solutions in areas such as special fibers, gaskets, seals, filters, and membranes that require both waterproofing and moisture permeability.

By securing manufacturing technology that utilizes a more flexible ePTFE membrane while maintaining the unique chemical, mechanical, and electrical properties of PTFE, Gore was able to develop a variety of products and solutions that were difficult to make with existing PTFE.

Cable products include insulators for communication cables that require high electrical properties, jackets for automation equipment, and cables for clean rooms.