Vacuum environment compatibility

Cables used in extreme high vacuum environments require completely different design technology than cables used in atmospheric pressure and require the highest level of cleanliness. Accordingly, dedicated production technology and facilities are essential for the production of cables for vacuum environments.

Manufacturing where vacuum

environments are essential

As the manufacturing technology of semiconductors and display panels advances rapidly, vacuum environments that require the highest level of cleanliness, where even the intervention of foreign substances below the molecular level is not permitted, are increasingly expanding in fields such as microprocessing.

Special characteristics

of vacuum environment

In a high vacuum environment of 10-7 Torr or less, it is more difficult for materials to maintain their own properties than at atmospheric pressure. Due to the low pressure, molecular bonds become loose and outgassing occurs, which can contaminate the inside of the chamber or cause materials to lose their own properties. In addition to outgassing, issues of various different types can occur while cables are flexing in a vacuum environment than at atmospheric pressure.

Cable manufacturing technology

suitable for vacuum environments

PTFE’s chemical stability prevents changes in properties and maintains cleanliness in high vacuum environments. In addition to the insulator and outer jacket, the conductors of cables operating in high vacuum chambers must be selected to be suitable for the vacuum environment.

Gore has a dedicated manufacturing process for manufacturing cables suitable for high vacuum environments, and conducts meticulous design, manufacturing process control, and rigorous testing to supply vacuum cables that meet customer requirements.

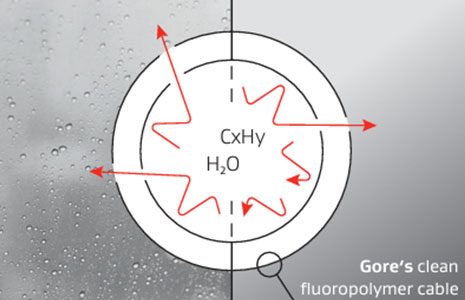

OUTGASSING

In the manufacturing of semiconductors, displays, etc., the main issue in OUTGASING inside the vacuum chamber is controlling hydrocarbons (CxHy) and moisture (H2O). Gore cables use the most chemically stable fluorine compounds, such as PTFE, as the covering and outer jacket, thereby fundamentally blocking other components remaining in the inner parts of the covering from escaping.

Experience in manufacturing

cables for various vacuum

environments

(Space, EUV, etc.)

Gore's cable products have been an integral part of space program NASA and ESA since the 1960s, and Gore have decades of experience manufacturing cables for vacuum environments.

Gore's vacuum cables are equipped in EUV equipment, which is essential for the ultra-fine processes of semiconductors, and are also being applied in various ways to many semiconductor and flat panel display manufacturing processes.