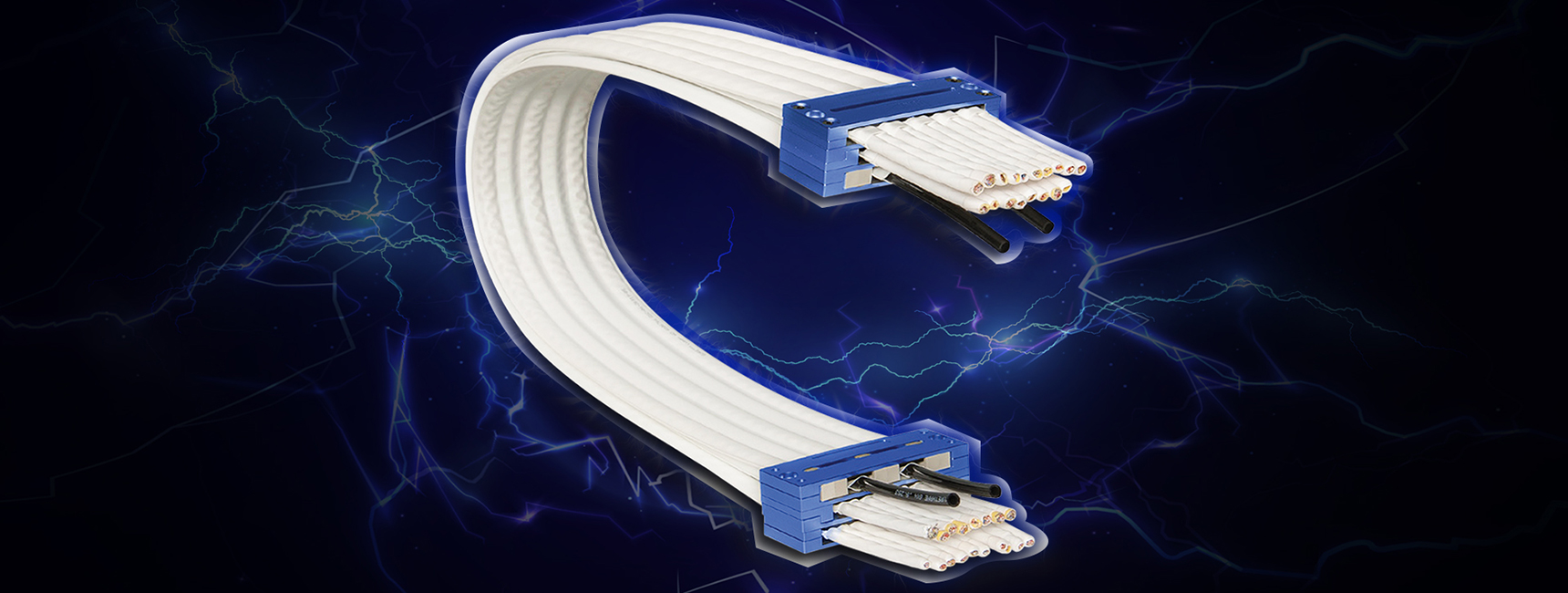

GORE® Trackless High Flex Cable

The world's first self-supporting clean cable system developed by Gore in 2005

GORE® Trackless High Flex Cables - Standard

In the form of a self-supporting flat cable without a separate cable carrier system, this product fundamentally solves the problems of particulation

at the joint of plastic carrier, particles due to friction with the installed cables in, and cables breakages that occur when the cable carrier flexing,

thereby drastically reducing particulate and improving cables flex life. By solving problems such as equipment downtime due to breakage, maintenance costs, and reduced yield due to particulate,

it provides a cost-saving effect that is incomparable to the cost caused by the increased purchase price of the cable system.

Highest level

of proven flex life

All cable cores used in GORE® Trackless High Flex Cables are designed and manufactured by Gore to ensure the highest level of electrical performance during the expected flex life. All cables designed and manufactured to the highest level are tested under conditions similar to actual environments and applied only when they meet the criteria.

All components and finished products of the standard GORE® Trackless High Flex Cable have been tested for at least 10 million flex cycles at 50mm bend radius, maximum acceleration of 4G, and 1.5m of stroke length, to ensure that there is no performance degradation. It has been applied to hundreds of thousands of manufacturing equipment of famous equipment manufacturers around the world, and its performance and reliability have been completely proven in the field.

GORE® Trackless High Flex Cables require each component to be placed and designed according to the operating conditions of the equipment to achieve optimal performance. Since 2007, UTRACS has been a team of experts who have specialized in designing and manufacturing related products, and have managed to manufacture them with the highest quality in dedicated manufacturing facilities by thoroughly reviewing the conditions of customers and performing the optimal design.

Breakthrough performance

of particulate reduction

GORE® Trackless High Flex Cable, a self-supporting flat cable, fundamentally eliminates the cause of particulation by eliminating the need for a separate cable transport track.

The cable jacket made of ePTFE, which has the lowest coefficient of friction among materials that can be used for cables, shows a different level of particulation than cable outer jackets made of other materials.

GORE® Trackless High Flex Cable has been certified by a third-party agency to satisfy ISO Class 1 under the flex conditions that a system using a conventional cable transport device shows ISO Class 5 level, and has also been certified to satisfy ISO Class 1 in an extended test of up to 1 million times.

Other benefits

-

Lightweight

Since there is no need for cable carriers separately and cable stacking is possible, the system weight and space are drastically reduced. By using special materials (ePTFE, PTFE, etc. ) that Gore's technology is concentrated in the jacket and insulations, the thickness can be drastically reduced compared to other round cables as well as similar products from other companies, which can significantly reduce the weight and space in the entire cable system. -

Convenience of installation

Installation is easy as it is delivered as a single assembly by stacking multiple layers of flat cables, so you only need to bolt it to the equipment without having to wire them individually. -

Minimum bending radius

By applying ePTFE, PTFE materials produced with Gore's original technology to the insulator and jacket and using conductors that match the actual environment and reliability goals, the targeted flex life performance (10 million times or more) can be satisfied even at the minimized bending radius (50 mm or less). -

Improved equipment precision

In addition to weight reduction, noise and vibration can be minimized to improve the precision of the equipment. The self-supporting internal components of a special structure, not a low-cost plastic chain type, are designed to enable smooth continuous operation without segmentation during operation, so there is no noise or vibration. -

Flex cable options for high data rates

As the specifications of equipment become higher and more advanced, special-purpose cables are required, but flex cables with guaranteed flex life are often not available on the market, so they cannot be used or cables for non-flexing applications are used that cannot satisfy reliability. Gore manufactures and stocks high-speed communication cables and other special-purpose cables required for the latest cameras applied to high-spec inspection equipment to satisfy the reliability required by automated equipment. (Example: Ethernet CAT 7, USB 3.1, Fiber Optic, Thermo Couple, etc.)

Applications

Flex cable system for automation equipment dedicated to clean rooms requiring particulate control

Flex cable system for automation equipment used in processes where cables reliability is important

Flex cable system for automation equipment requiring small quantities and short lead times

Flex cable system for automation equipment requiring high-speed data communication

Automation equipment requiring motion control of pneumatic and cooling water tubes

Actual application equipment

Display manufacturing equipment (most of the process including lithography), semiconductor pre- and post-process manufacturing equipment (inspection, bonding, packaging, handler, pick & place, OHT, etc.), camera manufacturing equipment (CMOS, lens, etc.), secondary battery manufacturing equipment

Mechanical / Environmental

| Property | Value |

|---|---|

| Jacket Material | Expanded PTFE composite |

| Jacket Color | White |

| Core Typesa) | Power, Signal, Fiber Optic, Pneumatic, etc. |

| Max. Self Supporting Stroke Lengthb) (mm) | 1500 |

| Min. Bending Radius b) (mm) | 50 |

| Max. Acceleration (G) | 4 |

| Max. Velocity (m/sec) | 4 |

| Expected Flex Life Cycles b) | Max 10 million cycles |

| Temperature Range (℃) | -40 ~ 80 |

| Cleanliness Class (ISO14664-1) | 1 |

| Particulation c) (ISO14664-1/ VDI Guideline 2083) | < 0.1 |

| Certification d) | UL, CE |

Reference the Core List of On-demand Flat

Product characteristics, operating conditions, and environmental factors may vary. (For further details, please consult Utracs representative.)

Details about the Cable Particulation Study for Cleanroom Environments from the Fraunhofer Institute are available at gore.com/particulation

UL Style 21090:80℃, pneumatic tubes are not UL certified

GORE® Anti-Static High Flex Cables

The manufacturing process of products sensitive to static electricity requires anti-static measures.

GORE® Anti-Static High Flex Cables uses a jacket made of specially engineered ePTFE material to control static electricity accumulated

on the outer jacket due to friction during flexing, so that static electricity generated due to friction during flexing is almost eliminated

without separate equipment or a grounding system.

GORE® Trackless High Flex Cable provided by UTRACS has the Anti-Static function applied as a mandatory feature.

Jacket with additional

Anti-Static function

GORE produces more than a thousand of products using ePTFE material, is an ePTFE specialist with numerous technologies and patents for related materials.

GORE® Anti-Static High Flex Cables goes beyond simply applying an anti-static coating and is manufactured by specially engineered ePTFE jacket material to exclude conductive carbon components. It was launched after conducting various tests step by step over many years from development to commercialization.

It prevents problems caused by static electricity, such as product damage due to ESD and capture of opposite-polarity particles, in advance, contributing to improving product productivity and yield.

GORE® Anti-Static High Flex Cables has been tested for 10 million flex cycles and has been proven to meet the standards required in the manufacturing processes of semiconductor and display panel by measuring surface resistance and voltage increase in real time.

Same level of reliability

and performance of particulate

reduction as the standard type

It was manufactured to ensure that there is no decrease in basic performance compared to the standard model due to the addition of the Anti-Static function, and it was confirmed that there is no decrease in performance through a more rigorous level of testing than the standard version.

It has been proven to have the same level of performance as the existing standard version through the results of environmental tests, durability tests, and operating life tests under various conditions several times in each stage.

The particulation test conducted by a third-party organization (Fraunhofer Institute) was extended beyond the standard test to 1 million times, satisfying ISO Class 1.

Other benefits

Easy compatibility with the standard type with 100% identical basic features.

The world's first cable system for cleanroom use that can be installed and used independently without the need for a separate device such as an ionizer for ESD countermeasures.

A product that has proven its performance in the actual field as a product that can be continuously supplied in serial production, not just at the level of simple technology development.

Improves the throughput of sensitive equipment that requires signal integrity by eliminating signal interference caused by noise generated by ESD.

Applications

(especially the following areas

where ESD measures are required)

Flex cable system for automation equipment dedicated to clean rooms requiring particulation control

Flex cable system for automation equipment used in processes where cable reliability is important

Flex cable system for automation equipment requiring small quantities and short lead times

Flex cable system for automation equipment requiring high-speed data communication

Automation equipment requiring movable motion control of pneumatic and cooling water tubes

Actual application equipment

Display manufacturing equipment (most of the process equipments), semiconductor pre- and post-process manufacturing equipment (inspection, bonding, packaging, handler, pick & place, OHT, etc.), camera manufacturing equipment (CMOS, lens, etc.), secondary battery manufacturing equipment

Electrical

| Property | Value |

|---|---|

| Surface Resistance (astm-d257, 45%rH, 23℃) | ≤ 109 |

|

Typical Charge Decaya Seconds (sec(DIN-EN 1149-5; 2008-04, 45% rH, 23℃)) |

<< 1 |

| Voltage Buildup a) (V (PLFWI-2730, up to 1000 cylces)) | << 100 |

Mechanical / Environmental

| Property | Value |

|---|---|

| Jacket Material | Expanded PTFE composite |

| Jacket Color | White |

| Core Typesb) | Power, Signal, Fiber Optic, Pneumatic, etc. |

| Max. Self Supporting Stroke Lengthc) (mm) | 1500 |

| Min. Bending Radius c) (mm) | 50 |

| Max. Acceleration (G) | 4 |

| Max. Velocity (m/sec) | 4 |

| Expected Flex Life Cycles c) | Max 10 million cycles |

| Temperature Range (℃) | -40 ~ 80 |

| Cleanliness Class (ISO14664-1) | 1 |

| Particulation d) (ISO14664-1/ VDI Guideline 2083) | < 0.1 |

| Certification e) | UL, CE |

Results may vary depending on the operating environment and conditions.

Reference the Core List of On-demand Flat

Product characteristics, operating conditions, and environmental factors may vary. (For further details, please consult Utracs representative.)

Details about the Cable Particulation Study for Cleanroom Environments from the Fraunhofer Institute are available at gore.com/particulation

UL Style 21090:80℃, pneumatic tubes are not UL certified

GORE® Trackless High Flex Cable - Long Stroke

Depending on the manufacturing process and product, flex cable systems often require the stroke lengths of 3 meters or more. In particular, in the case of flat panel display manufacturing equipment, as the size of the panel increases to meet the efficient processing volume of the product,

the stroke lengths of 4 to 5 meters may be required for cleanroom-specific flex cable systems.

GORE® Trackless High Flex Cable - Long Stroke has completed a flex life test for the stroke length of up to 5.5 meters.

Reliable flex life

for long-distance transport

The components for the self-supporting function of GORE® Trackless High Flex Cables for long stroke length must be designed completely differently from standard products to achieve the required flex life reliability. Having experienced that simply expanding the size of the standard type to make it stronger would cause various problems. Gore designed, analyzed, and tested countless types of support structure over the past decade to determine the size and shape of the components for self supporting and jacket, etc. with the optimized structure and size.

The reliability of long stroke cables can vary greatly depending on flex conditions and the total cable load, so it is most important for engineers with sufficient experience and knowledge to design the optimal assembly structure.

UTRACS provides consulting on additional mechanical structures required for equipment, as well as required performance analysis, from the initial design stage, so that the equipment can have the cable system of best flex life performance depending on the flex conditions of the equipment.

The flex life performance was also verified through flex tests under the conditions for flexing simultaneously in two perpendicular axes (X-axis, Y-axis) directions with additional lateral acceleration conditions.

Best particulate

reduction performance

As flexing for long stroke length, the amount of loads, stresses, and frictions applied to the cable system is significantly increased.

GORE® Trackless High Flex Cable - Long Stroke is designed to disperse and minimize the concentration of stress and friction caused by increased load.

It is applied to the main equipment of the world's leading display panel manufacturers, and it has been proven in the field that there is no particulation issues.

Available for Anti-Static

and Vacuum environment

Anti-Static functions can be applied by applying a low charging jacket.

It can be configured for use in a vacuum environment by using vacuum-specific components.

Applications

Flex cable system requiring long stroke length of automation equipment dedicated to clean rooms requiring particulation control

Flex cable system requiring long stroke length of automation equipment used in processes where cable reliability is important

Flex cable system requiring long stroke length of automation equipment requiring small quantities and short lead times

Flex cable system requiring long stroke length of automation equipment requiring high-speed data communication

Automation equipment requiring flex cable system of long stroke length that requires motion control of tubes for pneumatic and coolants

Actual application equipment

Display manufacturing equipment (most processes such as lithography), secondary battery manufacturing equipment, semiconductor pre- and post-process manufacturing equipment (inspection, bonding, packaging, handler, pick & place, etc.)

Mechanical / Environmental

| Property | Value | |

|---|---|---|

| One-axis motion | Two-axis (X, Y) motion | |

| Max. Self Supporting Stroke Length (mm) b) | 5500 | 5500 |

|

Max. Acceleration (G) X axis(along cable transport direction) Y axis(perpendicular to cable transport direction) |

2.5 |

2.5 0.3 |

| Max. Velocity (m/sec) | 2.5 | 2.5 |

| Core Typesa) | Power, Signal, Fiber Optic, Pneumatic, etc. | |

| Expected Flex Life Cycles b) | Max 10 million cycles | Max 5 million cycles |

| Min. Bending Radius b) (mm) | 150 | 150 |

| Temperature Range (℃) | -40 ~ 80 | |

| Certification c) | UL, CE | UL, CE |

Reference the Core List of On-demand Flat

Product characteristics, operating conditions, and environmental factors may vary. (For further details, please consult Utracs representative.)

UL Style 21090:80℃, pneumatic tubes are not UL certified

* Other technical specifications are the same as the standard / Anti-Static version.

GORE® Trackless High Flex Cable - Vacuum

Among the manufacturing processes for high-performance semiconductors and display panels,

there are equipment that require cables installed in vacuum environment.

Gore has accumulated experience and technology in vacuum environments, such as providing cables exclusively for EUV equipment.

Recently, there has been an increasing demand for cable systems that do not generate particles while operating inside a vacuum chamber,

and GORE® Trackless High Flex Cables, developed exclusively for vacuum environments, provides the perfect solution to this demand.

Cables for high vacuum

environments

The materials used in high vacuum environments below 10-7 Torr must have different properties from those used in atmospheric pressure.

Gore has been involved in various space programs since the 1960s and has manufactured vacuum-specific cables for decades, including cables for EUV equipment.

GORE® Trackless High Flex Cables, developed exclusively for vacuum environments, fundamentally solves equipment operation problems caused by high vacuum environments.

Best performance

for particulation control

and product cleanliness

GORE® Trackless High Flex Cables for vacuum environments are constructed to provide the same level of particulate reduction performance as standard or long stroke cables.

Due to the nature of the manufacturing process in a vacuum environment, particulate reduction is essential, and is manufactured on a dedicated manufacturing line to the highest possible level of cleanliness.

Cables and jackets manufactured in Gore’s vacuum-specific facility are finally assembled in vacuum-specific assembly facility of UTRACS.

Long Stroke is possible

Same level of performance for the longer stroke length as GORE® Trackless High Flex Cables - Long Stroke (long axis).

Applications

Flex cable system for high vacuum environments where cable reliability is important and particulate control is required

Flex cable system for high vacuum environments where long stroke length of flexing is required

Flex cable system for high vacuum environments where high-speed data communication is required

Flex cable system for high vacuum environments where motion control of tubes for pneumatic and coolants is required

Mechanical / Environmental

| Property | Value |

|---|---|

| Jacket Material | PTFE |

| Jacket Color | white |

| Core typesa) | Power, Signal, Fiber Optic, Pneumatic, etc. |

| Max. Self Supporting Stroke Lengthb) (mm) | 5500 |

| Min. Bending Radius b) (mm) | > 10 times of cable diameter |

| Max. Acceleration (G) | 2.5 |

| Max. Velocity (m/sec) | 2.5 |

| Expected Flex Life Cycles b) | Max 10 million cycles |

| Temperature Range (℃) | - 20 ~ 260 |

|

Outgassing rate (mBar x Iiter/sec x cm2)

H2O (AMU 18) c) CxHyv (volatile CxHy) (AMU 45-100) c) CxHynv (non-volatile CxHy) (AMU 101-200) c) |

4.00E-09 1.00E-10 6.00E-12 |

Reference the Core List of On-demand Flat

Product characteristics, operating conditions, and environmental factors may vary. (For further details, please consult Utracs representative.)

AMU = Atomic Mass Units