Flex Life Performance of Cables

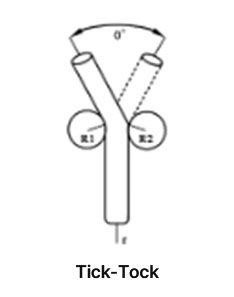

Cables flex in one or more of the four basic motions illustrated in below Figure.

Each time a cable bends or flexes, its copper conductors and shields are stressed. Copper has poor resistance to repeated stressing, even if the stress is kept below its ultimate yield point of 15 percent elongation. Copper also has very low resistance to shear stress and will deform even if the stress is below the plastic yield point.

To reduce fatigue on copper conductors and shields and thereby eliminate wire breakage, the cable's bend radius should be as large as possible, and the diameter of the cable should be as small as possible.

Solutions to prevent fatigue

failure of flexing conductors

and shielding

The most common type of cable-flex failure is the eventual fracture of the shield and/or conductor in the flex area.

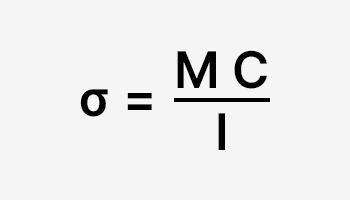

To understand the mechanism of conductor and shield failure, we must review the basic concepts of stress analysis. A rigid body's resistance to bending depends on the material, shape, area of the cross section, and radius of curvature of the bend. This is represented mathematically by the stress in the body, σ, given by:

- M Bending moment

- C Distance from the neutral axis of the body to any fiber in the cross section

- | Moment of inertia of the cross section

- σ Stress in the fiber at distance c

For a typical flex-cable application, the geometry of the bend is fixed by considerations including mechanical design constraints and package layout, so the designer must work within these constraints and minimize the conductor stresses that reduce flex life.

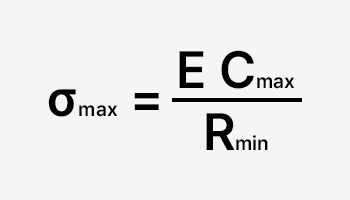

The most important factor in determining flex fatigue life is the maximum stress in any part of the cable. This maximum stress, assuming the bend radius does not go below a minimum value, R min, is given by:

- E Modulus of elasticity in psi (17,000,000 for ETP copper)

- Cmax Maximum distance from the neutral axis to any fiber

- Rmin Bend radius

Shielded flat-ribbon cable is self-supporting and can be used in most rolling, torsional, and tick-tock flex applications.

Note that this relationship holds for any cross section because the moment of inertia, |, does not appear.

Stress can be minimized by decreasing the cable thickness or diameter, Cmax, or by increasing the bend radius, Rmin. The effects of the stress can also be minimized by selecting conductor and shield materials that have higher tensile strength than copper.

Flexing tests show that the resistance of the copper conductors and shields increases as the metals work harder under flexing. The harder the metal is worked, the more brittle it becomes. Faster equipment cycle rates generate higher temperatures in the copper. A small bend radius also creates higher temperatures, as well as a higher degree of fatigue. The increased temperatures can create insulation softening, which in turn changes the insulation's physical properties, reducing abrasion resistance, decreasing cut-through resistance, and decreasing tensile strength. All of these changes can cause premature cable failure.

Solutions to prevent Fatigue

of the conductor and shield

at the point of termination

Bending stresses and vibration from moving cables cause connectors and crimped and soldered cable terminations to break. Unsupported cables fail prematurely due to fatigue at the connector interface. The flex life of the cable is determined by the installation and fixing the cables, and in the case of high-speed flexing cables, the design must be reflected so that the connectors ends are not affected, and should apply the solutions to prevent when installing the cable.

Other factors affecting

the flex life of the cable

Velocity, acceleration

Stroke Length

Weight of the cable

Interference with other components (cables, cable feeders, other machine parts, pneumatic tubing, etc.)

Installation

Advantages of using

flat cables

Using flat cables instead of multiple round cables significantly improves flex life performance for the following reasons:

Reduced weight compared to multiple round cables

Easier installation and maintenance

Reduced damage due to friction

Self-supporting, eliminating the need for cable transport devices